Everyone’s a Success in Class! Tips for Making a Clip Motor (A Hands-On Approach Using Corrugated Plastic)

Hi, I’m Ken Kuwako, a science trainer. Every day is an experiment!

Return to the “Otobutsu” Special Page

Have you ever heard of a “paperclip motor”? It’s a super simple motor made from a battery, some enameled wire, and a few paper clips. You might have even seen one in a science class or as part of a school project. It’s like “science magic” when the coil starts spinning! But here’s the thing: the paperclip motor has a little secret. While it looks so easy to make, it’s surprisingly difficult to get it to actually work.

With the usual instructions, many people end up with a motor that does absolutely nothing, no matter how hard they try. The main problem is how the coil is wound. If the coil isn’t a perfect circle or if the two ends aren’t perfectly straight, the motor won’t spin. It’s easy to get frustrated and think, “Maybe I’m just not cut out for this…”

Don’t give up just yet! Today, I’m going to share a brilliant trick that solves all those common frustrations. Believe it or not, you can use a common household item—plastic corrugated board—to build a paperclip motor that works every time! This mind-blowing method was taught to me by Mr. Eiji Komori. Are you ready to witness the magic of science with your own hands?

—

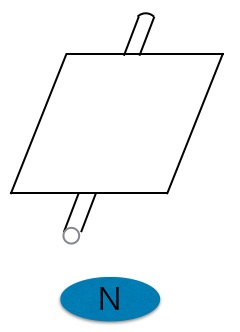

Understanding How a Paperclip Motor Works

A paperclip motor is a perfect example of electromagnetic induction, a principle that converts electrical energy into motion.

- Current and Magnetic Field: When an electric current from the battery flows through the enameled wire coil, it generates a magnetic field around the coil.

- Interaction with a Magnet: The magnetic field of the coil interacts with the magnetic field of a nearby magnet, creating a force that pushes the coil to spin.

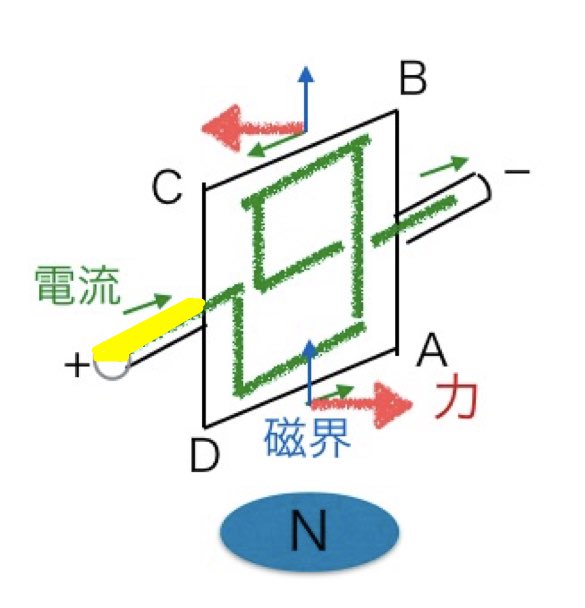

- Fleming’s Left-Hand Rule: The relationship between the current’s direction, the magnetic field’s direction, and the force’s direction is explained by “Fleming’s Left-Hand Rule.” This principle shows how the force generated by the current in the coil and the magnet’s field causes the coil to rotate.

—

The Key to Success: Winding the Coil. So Why is the Traditional Method So Hard?

Traditionally, people would wrap the enameled wire directly around a battery to form the coil. However, more than half the time, this method fails. The main reasons are:

- The coil ends are not straight: If the two ends aren’t perfectly aligned, the coil won’t spin smoothly. Even a slight bend can throw off the balance.

- It’s hard to make a perfect circle: For a consistent magnetic field, the coil must be a perfect circle. But getting it right by hand is surprisingly difficult.

—

Plastic Corrugated Board to the Rescue!

This is where plastic corrugated board comes in! By using it as a guide, you can solve both of these problems at once.

The benefits of using plastic corrugated board are numerous:

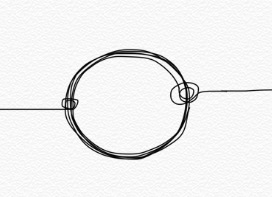

- Makes a perfect coil shape!: The board acts as a guide, so anyone can create a beautiful, circular coil easily.

- Shorter wire length is more economical!: You won’t waste any wire, which saves on materials.

- Easy to align the axis!: The thickness of the board helps ensure the two ends of the coil are perfectly straight.

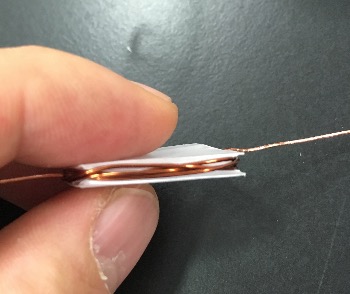

For this project, we used about 45cm of 0.5mm-diameter enameled wire. This thickness works well for creating a sturdy motor.

—

Let’s Get Started!

Use approximately 45 cm of enameled wire with a diameter of 0.5 mm. This thickness makes for a strong motor. We’ll use about 45cm of enameled wire with a diameter of 0.5mm. This thickness makes for a nice, sturdy motor.

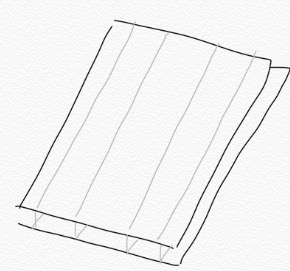

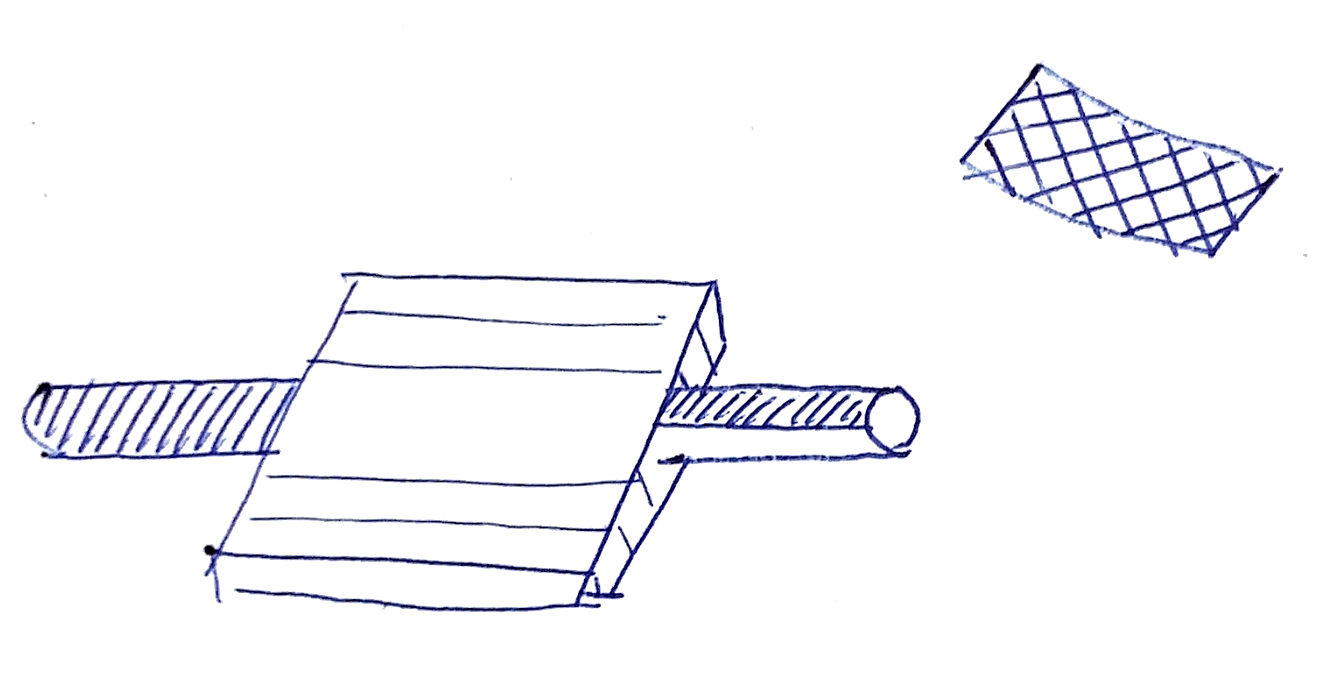

First, let’s look at how to wind the coil. Cut the plastic corrugated board like this:

The full instructions are in this video:

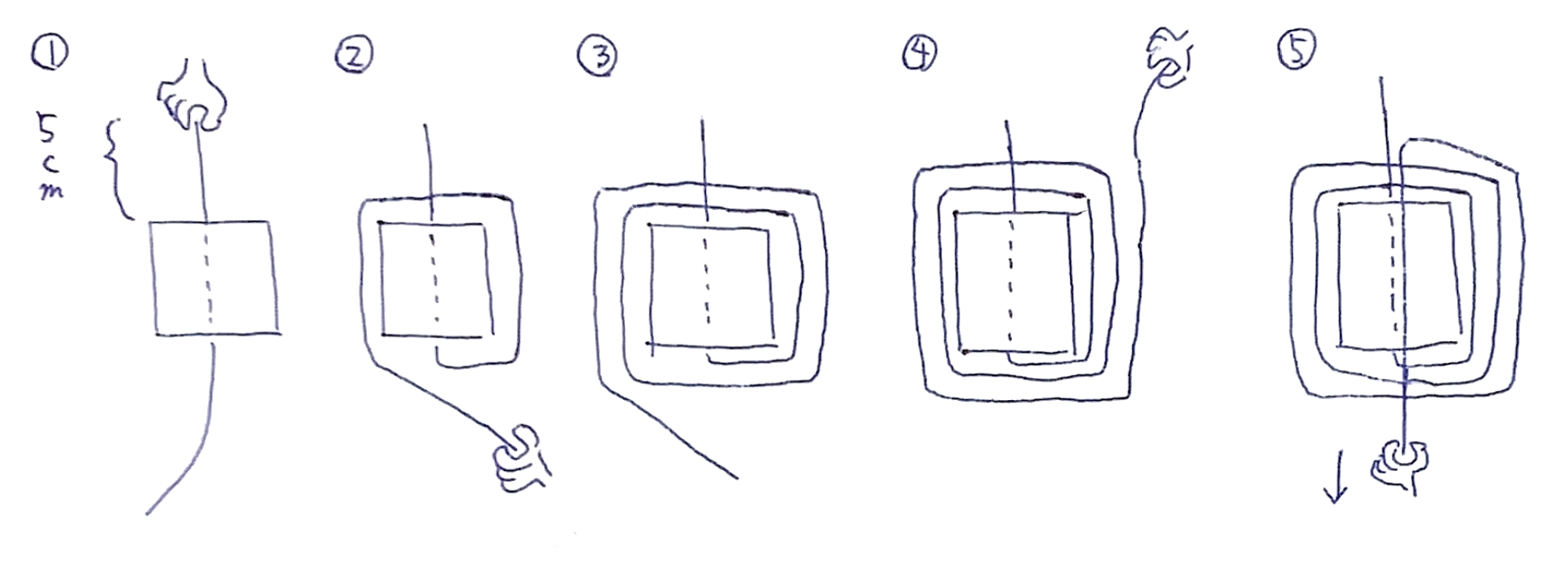

Cut the board to a length of 2.5cm, making sure there are three holes in a row when viewed from the side. Thread the wire through the middle hole, leaving about 5cm hanging out.

Follow the diagram to thread the wire. Finally, pull the wire a bit to tighten the shape and cut off the excess.

Now, use sandpaper to strip the insulation off the wires. On one end, strip the insulation off all the way around. On the other end, strip the insulation off only the top half. Make sure to strip the wire all the way to the base of the coil.

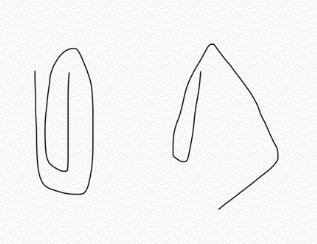

In the diagram, the gray parts are the stripped sections. Bend the paper clips like this:

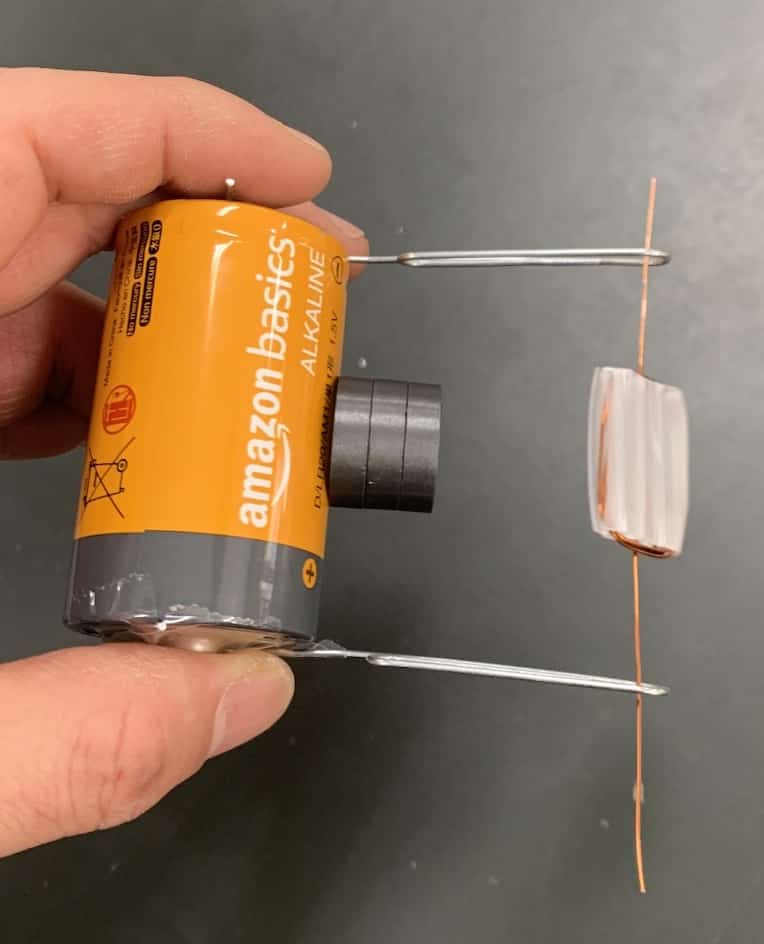

Then attach them to the battery like this:

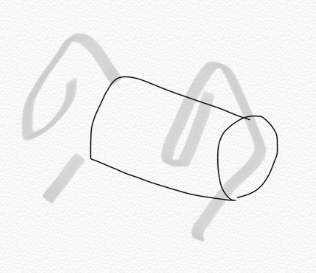

Attach a magnet to the battery, and you’re done! Place the coil on top.

Give it a little push, and it will start to spin!

What do you think? Give it a try at home!

What Happens If You Strip All the Insulation?

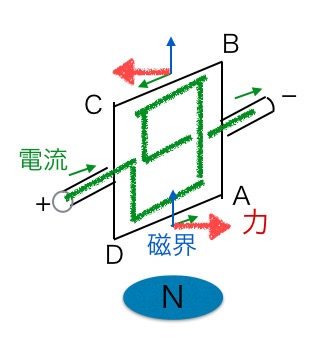

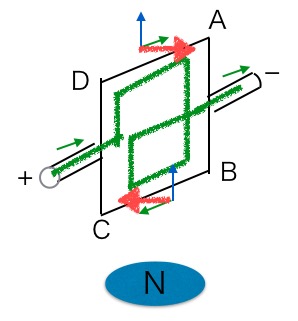

① When the coil and magnetic field are perfectly aligned (at 0°), the current flowing through the motor and the magnetic field from the magnet interact, creating a force. The coil rotates counter-clockwise.

*Note: The plastic board motor has more turns, but this diagram shows only one turn for clarity.

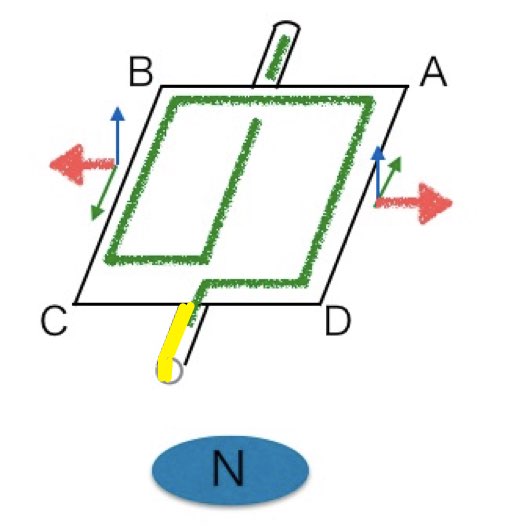

② When it rotates 90°, forces act on both ends of the coil, pushing it outward. This force does not cause rotation.

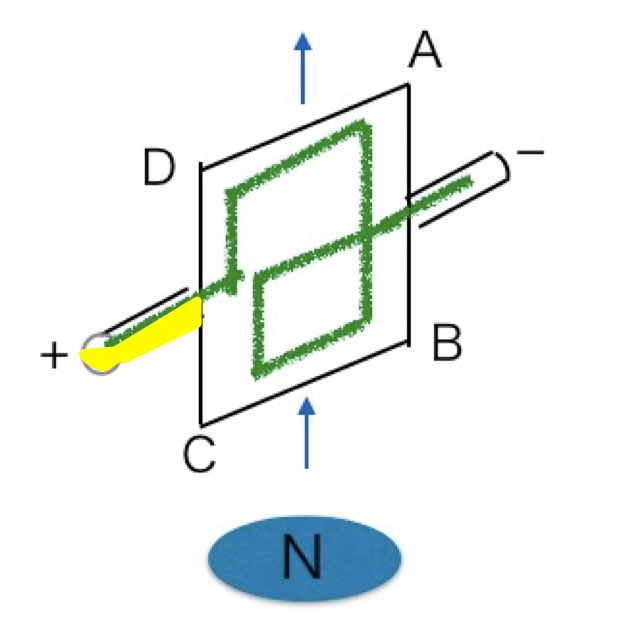

③ If it rotates 180° without a commutator, the direction of the current creates a clockwise force, and the motor will stop.

What Happens When You Add a Commutator?

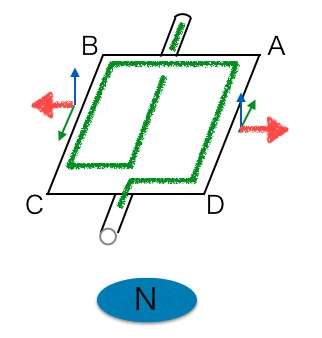

To solve this, we don’t strip the insulation from the top half of the enameled wire (the yellow part in the diagram).

①’ At 0°, the current flows through the bottom of the coil, which is touching the paper clips.

②’ Even at 90°, the current continues to flow since the bottom part is still touching the clips.

③’ When it rotates 180°, the insulated part is now on the bottom, so no current flows. This allows the coil’s counter-clockwise rotation to continue, and it returns to the position in ①’.

That’s all there is to it! What do you think? The paperclip motor is a simple motor that uses the power of electricity and magnets, but the key to success is how you wind the coil. By using plastic corrugated board, you can make a perfectly shaped coil and significantly increase your chances of success. Have fun building and exploring the world of science!

I think it’s a great idea to just provide the coil shape on a handout and have students draw the wire and current flow themselves. The diagrams may not be perfect, but I’ll share them with you to use if you like.

Return to the “Otobutsu” Special Page

Inquiries and Requests

Make the wonders and fun of science more accessible! I’ve put together easy-to-understand tips and tricks for fun science experiments you can do at home. Feel free to browse around!

・Learn more about the creator, Ken Kuwako, here

・For various requests (writing, lectures, workshops, TV supervision, appearances, etc.), please contact me here

・I post updates on new articles on X (formerly Twitter)!

![]() The Science Channel is where I post my experiment videos!

The Science Channel is where I post my experiment videos!

3月のイチオシ実験!電気スライム

- みんなが大好きスライム作り。手作りだけ楽しんで終わりじゃもったいない・せっかくなので電気を流してみよう!電気回路の学習にもなります!

テレビ番組・科学監修等のお知らせ

- 「月曜から夜更かし」(日本テレビ)にて科学監修・出演しました。

- 2月27日放送予定「チコちゃんに叱られる」(NHK)の科学監修しました。

書籍のお知らせ

- 1/27 『見えない力と遊ぼう!電気・磁石・熱の実験』(工学社)を執筆しました。

- サクセス15 2月号にて「浸透圧」に関する科学記事を執筆しました。

- 『大人のための高校物理復習帳』(講談社)…一般向けに日常の物理について公式を元に紐解きました。特設サイトでは実験を多数紹介しています。※増刷がかかり6刷となりました(2026/02/01)

- 『きめる!共通テスト 物理基礎 改訂版』(学研)… 高校物理の参考書です。イラストを多くしてイメージが持てるように描きました。授業についていけない、物理が苦手、そんな生徒におすすめです。特設サイトはこちら。

講師・ショー・その他お知らせ

- 3/20(金) 日本理科教育学会オンライン全国大会2026「慣性の法則の概念形成を目指した探究的な学びの実践」について発表します。B会場 第3セッション: 学習指導・教材(中学校)③ 11:20-12:20

- 7/18(土) 教員向け実験講習会「ナリカカサイエンスアカデミー」の講師をします。お会いしましょう。

- 10/10(土) 秘密兵器「帯電ガン」が炸裂!ビリビリ!ドキドキ!静電気サイエンスショー@千葉市科学フェスタ(午後予定)

- 各種SNS X(Twitter)/instagram/Facebook/BlueSky/Threads

Explore

- 楽しい実験…お子さんと一緒に夢中になれるイチオシの科学実験を多数紹介しています。また、高校物理の理解を深めるための動画教材も用意しました。

- 理科の教材… 理科教師をバックアップ!授業の質を高め、準備を効率化するための選りすぐりの教材を紹介しています。

- Youtube…科学実験等の動画を配信しています。

- 科学ラジオ …科学トピックをほぼ毎日配信中!AI技術を駆使して作成した「耳で楽しむ科学」をお届けします。

- 講演 …全国各地で実験講習会・サイエンスショー等を行っています。

- About …「科学のネタ帳」のコンセプトや、運営者である桑子研のプロフィール・想いをまとめています。

- お問い合わせ …実験教室のご依頼、執筆・講演の相談、科学監修等はこちらのフォームからお寄せください。

- What’s That Force in Your Coffee Cup? Discover the Amazing World of “Centrifugal Force” Through Science! (Spinning Rides)

- Why Do Soap Bubbles Rush Toward Static Electricity—While Paper Butterflies Flee? The Shocking Science Explained!

- The Closet Guardian! The Surprising Science Hidden in the “White Beads” of Moisture Absorbers (Calcium Chloride)

- Never Miss Your Target! The Strange Law That Guarantees a Hit—The Monkey Hunting Game Explained

- The Coin That Won’t Come Out—Solved in a Split Second with Physics! The Coin Escape Puzzle

- Create a Rainbow! The Science Behind Double Rainbows, Refraction, and Reflection Painting the Sky

- What Happens When Waves Collide? Explore Superposition with a DIY Scratch Simulator!

- Two BeeSpies, One Trick! A Mind-Blowing Experiment to Visualize Motion Equations

- Why Do Waves Bend? Master the Tough Huygens’ Principle with a Magical Simulation (Scratch)